The

project has just moved into the ITL Aviation hangar at Fielding in

December 2003 ready for the project start. Although originally built at

the Castle Bromwich factory in September 1944, the aircraft had also been

re furbished in Israel. The restoration at ITL Aviation will return the

aircraft to "new", zero time condition The

project has just moved into the ITL Aviation hangar at Fielding in

December 2003 ready for the project start. Although originally built at

the Castle Bromwich factory in September 1944, the aircraft had also been

re furbished in Israel. The restoration at ITL Aviation will return the

aircraft to "new", zero time condition |

By

February 2004 the fuselage jig is being built up around the fuselage which

has had the outer skins removed. Around 25 years on a pole had taken its toll on

the lower fuselage in particular. The airframe had been attached to its

pole mount by bolts through the lower longerons which were then cut

through when it was removed By

February 2004 the fuselage jig is being built up around the fuselage which

has had the outer skins removed. Around 25 years on a pole had taken its toll on

the lower fuselage in particular. The airframe had been attached to its

pole mount by bolts through the lower longerons which were then cut

through when it was removed |

June

2004 and frame refurbishment is underway. Because of the way the aircraft

had been mounted for display, considerable damage had been done to the

bottom longeron behind the main join. Both bottom longerons have been

replaced with newly fabricated units June

2004 and frame refurbishment is underway. Because of the way the aircraft

had been mounted for display, considerable damage had been done to the

bottom longeron behind the main join. Both bottom longerons have been

replaced with newly fabricated units |

July

2004 and datum longerons have been re furbished and some frames. The

bottom longerons, datum longerons and top longeron form the main

longitudinal structure of the fuselage with the frames (from frame 5 the

firewall, to frame 19 where the tail section is bolted on) providing the

shaping for the skins. The Mk IX is essentially a Mk 5 with two stage

Merlin and heavier gauge skins as well as a number of minor modifications July

2004 and datum longerons have been re furbished and some frames. The

bottom longerons, datum longerons and top longeron form the main

longitudinal structure of the fuselage with the frames (from frame 5 the

firewall, to frame 19 where the tail section is bolted on) providing the

shaping for the skins. The Mk IX is essentially a Mk 5 with two stage

Merlin and heavier gauge skins as well as a number of minor modifications |

October

2004 and rebuild of the cockpit coming and part of frame 5 (which includes

the carry through spars) is nearing

completion. The firewall originally contained an asbestos fireproof

material between the sheet layers. In one of the few concessions to

progress, this has been replaced with a modern material. The area forward

of the cockpit housed the two fuel tanks. October

2004 and rebuild of the cockpit coming and part of frame 5 (which includes

the carry through spars) is nearing

completion. The firewall originally contained an asbestos fireproof

material between the sheet layers. In one of the few concessions to

progress, this has been replaced with a modern material. The area forward

of the cockpit housed the two fuel tanks. |

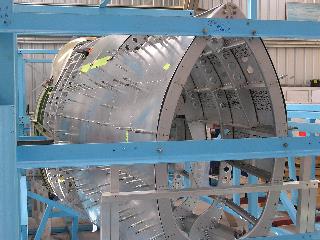

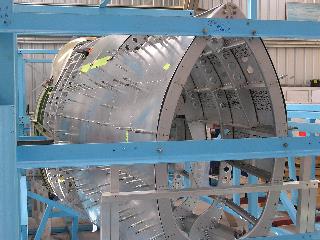

January

2005 - a number of fuselage frames have been refurbished, repaired

or replaced. Original skins are used to check alignment and fit. The

battery tray structure can be seen to the right of the rear fuselage. January

2005 - a number of fuselage frames have been refurbished, repaired

or replaced. Original skins are used to check alignment and fit. The

battery tray structure can be seen to the right of the rear fuselage. |

February

2005 - disassembly of one of the wings begins. Like the fuselage, the

wings will be completely stripped down to individual components. The main

components of each "D" section are the spars, spar webs and nose

ribs plus a myriad of other fixtures and fittings, virtually all Spitfire

specific February

2005 - disassembly of one of the wings begins. Like the fuselage, the

wings will be completely stripped down to individual components. The main

components of each "D" section are the spars, spar webs and nose

ribs plus a myriad of other fixtures and fittings, virtually all Spitfire

specific |

August

2005 - fuselage structure completed and re skinning of the fuselage has

started in earnest. Sheet to the original specification has been sourced

from England to maintain the authenticity of the rebuild August

2005 - fuselage structure completed and re skinning of the fuselage has

started in earnest. Sheet to the original specification has been sourced

from England to maintain the authenticity of the rebuild |

October

2005 - fuselage taking shape. The rebuild of PV270 has been as faithful to

the original factory specification as is possible and original materials

are used throughout - including British aluminum, rivets and AGS

fittings October

2005 - fuselage taking shape. The rebuild of PV270 has been as faithful to

the original factory specification as is possible and original materials

are used throughout - including British aluminum, rivets and AGS

fittings |

December

2005 - fuselage skinning largely complete. Access doors left off to

assist access to the inside structure. The "shape" of the

Spitfire is complex requiring a number of curved panels to be

"wheeled" into shape using the same techniques used in wartime

Spitfire production. December

2005 - fuselage skinning largely complete. Access doors left off to

assist access to the inside structure. The "shape" of the

Spitfire is complex requiring a number of curved panels to be

"wheeled" into shape using the same techniques used in wartime

Spitfire production. |

February

2006 - Pete Burgess working on the alignment of the rebuilt canopy. The

canopy guide on the port side includes a section fitted to the cockpit

door. The latch assembly on the door could be set to have the door

partially open which in turn stopped the canopy slipping forward in the

event of a take off accident February

2006 - Pete Burgess working on the alignment of the rebuilt canopy. The

canopy guide on the port side includes a section fitted to the cockpit

door. The latch assembly on the door could be set to have the door

partially open which in turn stopped the canopy slipping forward in the

event of a take off accident |

March

2006 - Tail section taking shape in the jig. Key elements such as spars

were re built because of corrosion to the originals March

2006 - Tail section taking shape in the jig. Key elements such as spars

were re built because of corrosion to the originals |

May

2006 - looking forward into the rebuilt fuselage with pilots seat fitted

and empty instrument panel. The structure midway down the fuselage was the

support for the slide in radio tray allowing it to be easily removed for

servicing. An original TR1143 radio set as fitted to this aircraft in the

factory has been obtained for historical completeness (although modern

radio, transponder and ELT will be fitted) May

2006 - looking forward into the rebuilt fuselage with pilots seat fitted

and empty instrument panel. The structure midway down the fuselage was the

support for the slide in radio tray allowing it to be easily removed for

servicing. An original TR1143 radio set as fitted to this aircraft in the

factory has been obtained for historical completeness (although modern

radio, transponder and ELT will be fitted) |

July

2006 - one of the wing "D" sections rebuilt and waiting to be

mated with the spars and spar webs. The leading edge skins are one piece

and "wheeled" into the complex shape required. The "D"

sections are the key to the enormous strength of the Spitfire wing July

2006 - one of the wing "D" sections rebuilt and waiting to be

mated with the spars and spar webs. The leading edge skins are one piece

and "wheeled" into the complex shape required. The "D"

sections are the key to the enormous strength of the Spitfire wing |

August

2006 - starboard wing structure after refurbishment and being trial

assembled using the original spars. The structure for the ammunition

magazines for the Browning machine guns can be seen in the centre.

Although new main and rear spars have been fabricated, the spar webs and

most of the wing ribs have been restored August

2006 - starboard wing structure after refurbishment and being trial

assembled using the original spars. The structure for the ammunition

magazines for the Browning machine guns can be seen in the centre.

Although new main and rear spars have been fabricated, the spar webs and

most of the wing ribs have been restored |

September

2006 - Joe Deere working on the upper one of the two fuel tanks. Total

fuel capacity is only 85 gallons so additional tanks are to be fitted

where the cannons were originally mounted on the aircraft. This will

almost double the range of the aircraft. Only the bottom tank was gauged

so no indication of fuel remaining was given to the pilot until the top

tank was empty September

2006 - Joe Deere working on the upper one of the two fuel tanks. Total

fuel capacity is only 85 gallons so additional tanks are to be fitted

where the cannons were originally mounted on the aircraft. This will

almost double the range of the aircraft. Only the bottom tank was gauged

so no indication of fuel remaining was given to the pilot until the top

tank was empty |

November

2006 - These

components are from one of the wing "D" sections. They are

mostly original parts with some new replacements built where the originals

were damaged. The original components are bead blasted to remove surface

corrosion, inspected/crack tested, re anodised and painted before returning to the airframe November

2006 - These

components are from one of the wing "D" sections. They are

mostly original parts with some new replacements built where the originals

were damaged. The original components are bead blasted to remove surface

corrosion, inspected/crack tested, re anodised and painted before returning to the airframe |

December

2006 - new spars being mated with the spar webs prior to joining with the

previously completed "D" sections. Each wing has two spars which

are made of multiple sections fitting inside each other and then bent to

achieve the required wing dihedral. The assemblies also carry the fittings

to attach the wing ribs. The spar sections reduce the further out on

the wing, starting with six and dropping down to half of one section at

the wing tip December

2006 - new spars being mated with the spar webs prior to joining with the

previously completed "D" sections. Each wing has two spars which

are made of multiple sections fitting inside each other and then bent to

achieve the required wing dihedral. The assemblies also carry the fittings

to attach the wing ribs. The spar sections reduce the further out on

the wing, starting with six and dropping down to half of one section at

the wing tip |

January

2007 - tail section rebuild nearing completion with completed fuselage in

the background. Fuselage belly skins, access doors and some side panels have been

completed but left off to

enable access for wiring and systems fit out. The bottom skins on the tail

plane include fixing by brass screws to wooden bearers as there

was no access for riveting January

2007 - tail section rebuild nearing completion with completed fuselage in

the background. Fuselage belly skins, access doors and some side panels have been

completed but left off to

enable access for wiring and systems fit out. The bottom skins on the tail

plane include fixing by brass screws to wooden bearers as there

was no access for riveting |

February

2007 - starboard wing ribs and structure being assembled onto the

completed starboard "D" section. Because of the good condition

of the original wings, virtually all of the fittings associated with the

mounting of the machine guns and cannons have been preserved, including

the adjusters used to harmonise and aim the guns February

2007 - starboard wing ribs and structure being assembled onto the

completed starboard "D" section. Because of the good condition

of the original wings, virtually all of the fittings associated with the

mounting of the machine guns and cannons have been preserved, including

the adjusters used to harmonise and aim the guns |

March

2007 - the tail section has been completed ready for internal control

fittings. Restoration of the rudder is progressing and restoration of the

elevator has yet to start March

2007 - the tail section has been completed ready for internal control

fittings. Restoration of the rudder is progressing and restoration of the

elevator has yet to start |

April

2007 - skinning has begun on the starboard wing April

2007 - skinning has begun on the starboard wing |

May

2007 - the completed tail assembly has been bolted to the main fuselage May

2007 - the completed tail assembly has been bolted to the main fuselage |

June

2007- The

engine mount assembly is fitted to the fuselage frame 5 and to the jig.

The tubular structure has to cope with the huge torsion loads imposed by

the 1,500 hp Merlin engine June

2007- The

engine mount assembly is fitted to the fuselage frame 5 and to the jig.

The tubular structure has to cope with the huge torsion loads imposed by

the 1,500 hp Merlin engine |

July

2007 - The

second of two newly built flaps nears completion July

2007 - The

second of two newly built flaps nears completion |

August

2007 - Wing skinning well advanced August

2007 - Wing skinning well advanced |

September

2007 - trial fitting one of the radiator intake assemblies. Each intake

assembly houses two radiators - on one wing a coolant radiator and oil

cooler and on the other side another coolant radiator and the intercooler

radiator. September

2007 - trial fitting one of the radiator intake assemblies. Each intake

assembly houses two radiators - on one wing a coolant radiator and oil

cooler and on the other side another coolant radiator and the intercooler

radiator. |

October

2007 - view of the fuselage and wings in their respective jigs with the

tail assembly removed for final shimming October

2007 - view of the fuselage and wings in their respective jigs with the

tail assembly removed for final shimming |

November

2007 - construction of the wing tips underway. November

2007 - construction of the wing tips underway. |

December

2007 - general view of progress at the end of the year December

2007 - general view of progress at the end of the year |

January

2008 - starboard wing with radiators and shroud fitted January

2008 - starboard wing with radiators and shroud fitted |

February

2008 - the medium sea grey final coat being applied to the underside of

the flap area February

2008 - the medium sea grey final coat being applied to the underside of

the flap area |

March

2008 - Port aileron nearing completion March

2008 - Port aileron nearing completion |

April

2008 - the arrival of our re furbished Merlin 70 engine was a significant

milestone April

2008 - the arrival of our re furbished Merlin 70 engine was a significant

milestone |

May

2008 - Engine is installed in airframe May

2008 - Engine is installed in airframe |

June

2008 - Undercarriage assemblies are aligned in wings June

2008 - Undercarriage assemblies are aligned in wings |

By

February 2004 the fuselage jig is being built up around the fuselage which

has had the outer skins removed. Around 25 years on a pole had taken its toll on

the lower fuselage in particular. The airframe had been attached to its

pole mount by bolts through the lower longerons which were then cut

through when it was removed

By

February 2004 the fuselage jig is being built up around the fuselage which

has had the outer skins removed. Around 25 years on a pole had taken its toll on

the lower fuselage in particular. The airframe had been attached to its

pole mount by bolts through the lower longerons which were then cut

through when it was removed June

2004 and frame refurbishment is underway. Because of the way the aircraft

had been mounted for display, considerable damage had been done to the

bottom longeron behind the main join. Both bottom longerons have been

replaced with newly fabricated units

June

2004 and frame refurbishment is underway. Because of the way the aircraft

had been mounted for display, considerable damage had been done to the

bottom longeron behind the main join. Both bottom longerons have been

replaced with newly fabricated units July

2004 and datum longerons have been re furbished and some frames. The

bottom longerons, datum longerons and top longeron form the main

longitudinal structure of the fuselage with the frames (from frame 5 the

firewall, to frame 19 where the tail section is bolted on) providing the

shaping for the skins. The Mk IX is essentially a Mk 5 with two stage

Merlin and heavier gauge skins as well as a number of minor modifications

July

2004 and datum longerons have been re furbished and some frames. The

bottom longerons, datum longerons and top longeron form the main

longitudinal structure of the fuselage with the frames (from frame 5 the

firewall, to frame 19 where the tail section is bolted on) providing the

shaping for the skins. The Mk IX is essentially a Mk 5 with two stage

Merlin and heavier gauge skins as well as a number of minor modifications October

2004 and rebuild of the cockpit coming and part of frame 5 (which includes

the carry through spars) is nearing

completion. The firewall originally contained an asbestos fireproof

material between the sheet layers. In one of the few concessions to

progress, this has been replaced with a modern material. The area forward

of the cockpit housed the two fuel tanks.

October

2004 and rebuild of the cockpit coming and part of frame 5 (which includes

the carry through spars) is nearing

completion. The firewall originally contained an asbestos fireproof

material between the sheet layers. In one of the few concessions to

progress, this has been replaced with a modern material. The area forward

of the cockpit housed the two fuel tanks.  January

2005 - a number of fuselage frames have been refurbished, repaired

or replaced. Original skins are used to check alignment and fit. The

battery tray structure can be seen to the right of the rear fuselage.

January

2005 - a number of fuselage frames have been refurbished, repaired

or replaced. Original skins are used to check alignment and fit. The

battery tray structure can be seen to the right of the rear fuselage. February

2005 - disassembly of one of the wings begins. Like the fuselage, the

wings will be completely stripped down to individual components. The main

components of each "D" section are the spars, spar webs and nose

ribs plus a myriad of other fixtures and fittings, virtually all Spitfire

specific

February

2005 - disassembly of one of the wings begins. Like the fuselage, the

wings will be completely stripped down to individual components. The main

components of each "D" section are the spars, spar webs and nose

ribs plus a myriad of other fixtures and fittings, virtually all Spitfire

specific August

2005 - fuselage structure completed and re skinning of the fuselage has

started in earnest. Sheet to the original specification has been sourced

from England to maintain the authenticity of the rebuild

August

2005 - fuselage structure completed and re skinning of the fuselage has

started in earnest. Sheet to the original specification has been sourced

from England to maintain the authenticity of the rebuild October

2005 - fuselage taking shape. The rebuild of PV270 has been as faithful to

the original factory specification as is possible and original materials

are used throughout - including British aluminum, rivets and AGS

fittings

October

2005 - fuselage taking shape. The rebuild of PV270 has been as faithful to

the original factory specification as is possible and original materials

are used throughout - including British aluminum, rivets and AGS

fittings  December

2005 - fuselage skinning largely complete. Access doors left off to

assist access to the inside structure. The "shape" of the

Spitfire is complex requiring a number of curved panels to be

"wheeled" into shape using the same techniques used in wartime

Spitfire production.

December

2005 - fuselage skinning largely complete. Access doors left off to

assist access to the inside structure. The "shape" of the

Spitfire is complex requiring a number of curved panels to be

"wheeled" into shape using the same techniques used in wartime

Spitfire production. February

2006 - Pete Burgess working on the alignment of the rebuilt canopy. The

canopy guide on the port side includes a section fitted to the cockpit

door. The latch assembly on the door could be set to have the door

partially open which in turn stopped the canopy slipping forward in the

event of a take off accident

February

2006 - Pete Burgess working on the alignment of the rebuilt canopy. The

canopy guide on the port side includes a section fitted to the cockpit

door. The latch assembly on the door could be set to have the door

partially open which in turn stopped the canopy slipping forward in the

event of a take off accident March

2006 - Tail section taking shape in the jig. Key elements such as spars

were re built because of corrosion to the originals

March

2006 - Tail section taking shape in the jig. Key elements such as spars

were re built because of corrosion to the originals May

2006 - looking forward into the rebuilt fuselage with pilots seat fitted

and empty instrument panel. The structure midway down the fuselage was the

support for the slide in radio tray allowing it to be easily removed for

servicing. An original TR1143 radio set as fitted to this aircraft in the

factory has been obtained for historical completeness (although modern

radio, transponder and ELT will be fitted)

May

2006 - looking forward into the rebuilt fuselage with pilots seat fitted

and empty instrument panel. The structure midway down the fuselage was the

support for the slide in radio tray allowing it to be easily removed for

servicing. An original TR1143 radio set as fitted to this aircraft in the

factory has been obtained for historical completeness (although modern

radio, transponder and ELT will be fitted) July

2006 - one of the wing "D" sections rebuilt and waiting to be

mated with the spars and spar webs. The leading edge skins are one piece

and "wheeled" into the complex shape required. The "D"

sections are the key to the enormous strength of the Spitfire wing

July

2006 - one of the wing "D" sections rebuilt and waiting to be

mated with the spars and spar webs. The leading edge skins are one piece

and "wheeled" into the complex shape required. The "D"

sections are the key to the enormous strength of the Spitfire wing August

2006 - starboard wing structure after refurbishment and being trial

assembled using the original spars. The structure for the ammunition

magazines for the Browning machine guns can be seen in the centre.

Although new main and rear spars have been fabricated, the spar webs and

most of the wing ribs have been restored

August

2006 - starboard wing structure after refurbishment and being trial

assembled using the original spars. The structure for the ammunition

magazines for the Browning machine guns can be seen in the centre.

Although new main and rear spars have been fabricated, the spar webs and

most of the wing ribs have been restored September

2006 - Joe Deere working on the upper one of the two fuel tanks. Total

fuel capacity is only 85 gallons so additional tanks are to be fitted

where the cannons were originally mounted on the aircraft. This will

almost double the range of the aircraft. Only the bottom tank was gauged

so no indication of fuel remaining was given to the pilot until the top

tank was empty

September

2006 - Joe Deere working on the upper one of the two fuel tanks. Total

fuel capacity is only 85 gallons so additional tanks are to be fitted

where the cannons were originally mounted on the aircraft. This will

almost double the range of the aircraft. Only the bottom tank was gauged

so no indication of fuel remaining was given to the pilot until the top

tank was empty November

2006 - These

components are from one of the wing "D" sections. They are

mostly original parts with some new replacements built where the originals

were damaged. The original components are bead blasted to remove surface

corrosion, inspected/crack tested, re anodised and painted before returning to the airframe

November

2006 - These

components are from one of the wing "D" sections. They are

mostly original parts with some new replacements built where the originals

were damaged. The original components are bead blasted to remove surface

corrosion, inspected/crack tested, re anodised and painted before returning to the airframe December

2006 - new spars being mated with the spar webs prior to joining with the

previously completed "D" sections. Each wing has two spars which

are made of multiple sections fitting inside each other and then bent to

achieve the required wing dihedral. The assemblies also carry the fittings

to attach the wing ribs. The spar sections reduce the further out on

the wing, starting with six and dropping down to half of one section at

the wing tip

December

2006 - new spars being mated with the spar webs prior to joining with the

previously completed "D" sections. Each wing has two spars which

are made of multiple sections fitting inside each other and then bent to

achieve the required wing dihedral. The assemblies also carry the fittings

to attach the wing ribs. The spar sections reduce the further out on

the wing, starting with six and dropping down to half of one section at

the wing tip January

2007 - tail section rebuild nearing completion with completed fuselage in

the background. Fuselage belly skins, access doors and some side panels have been

completed but left off to

enable access for wiring and systems fit out. The bottom skins on the tail

plane include fixing by brass screws to wooden bearers as there

was no access for riveting

January

2007 - tail section rebuild nearing completion with completed fuselage in

the background. Fuselage belly skins, access doors and some side panels have been

completed but left off to

enable access for wiring and systems fit out. The bottom skins on the tail

plane include fixing by brass screws to wooden bearers as there

was no access for riveting February

2007 - starboard wing ribs and structure being assembled onto the

completed starboard "D" section. Because of the good condition

of the original wings, virtually all of the fittings associated with the

mounting of the machine guns and cannons have been preserved, including

the adjusters used to harmonise and aim the guns

February

2007 - starboard wing ribs and structure being assembled onto the

completed starboard "D" section. Because of the good condition

of the original wings, virtually all of the fittings associated with the

mounting of the machine guns and cannons have been preserved, including

the adjusters used to harmonise and aim the guns March

2007 - the tail section has been completed ready for internal control

fittings. Restoration of the rudder is progressing and restoration of the

elevator has yet to start

March

2007 - the tail section has been completed ready for internal control

fittings. Restoration of the rudder is progressing and restoration of the

elevator has yet to start April

2007 - skinning has begun on the starboard wing

April

2007 - skinning has begun on the starboard wing May

2007 - the completed tail assembly has been bolted to the main fuselage

May

2007 - the completed tail assembly has been bolted to the main fuselage June

2007- The

engine mount assembly is fitted to the fuselage frame 5 and to the jig.

The tubular structure has to cope with the huge torsion loads imposed by

the 1,500 hp Merlin engine

June

2007- The

engine mount assembly is fitted to the fuselage frame 5 and to the jig.

The tubular structure has to cope with the huge torsion loads imposed by

the 1,500 hp Merlin engine July

2007 - The

second of two newly built flaps nears completion

July

2007 - The

second of two newly built flaps nears completion August

2007 - Wing skinning well advanced

August

2007 - Wing skinning well advanced September

2007 - trial fitting one of the radiator intake assemblies. Each intake

assembly houses two radiators - on one wing a coolant radiator and oil

cooler and on the other side another coolant radiator and the intercooler

radiator.

September

2007 - trial fitting one of the radiator intake assemblies. Each intake

assembly houses two radiators - on one wing a coolant radiator and oil

cooler and on the other side another coolant radiator and the intercooler

radiator. October

2007 - view of the fuselage and wings in their respective jigs with the

tail assembly removed for final shimming

October

2007 - view of the fuselage and wings in their respective jigs with the

tail assembly removed for final shimming November

2007 - construction of the wing tips underway.

November

2007 - construction of the wing tips underway.  December

2007 - general view of progress at the end of the year

December

2007 - general view of progress at the end of the year January

2008 - starboard wing with radiators and shroud fitted

January

2008 - starboard wing with radiators and shroud fitted  February

2008 - the medium sea grey final coat being applied to the underside of

the flap area

February

2008 - the medium sea grey final coat being applied to the underside of

the flap area March

2008 - Port aileron nearing completion

March

2008 - Port aileron nearing completion April

2008 - the arrival of our re furbished Merlin 70 engine was a significant

milestone

April

2008 - the arrival of our re furbished Merlin 70 engine was a significant

milestone May

2008 - Engine is installed in airframe

May

2008 - Engine is installed in airframe June

2008 - Undercarriage assemblies are aligned in wings

June

2008 - Undercarriage assemblies are aligned in wings